Device built-in

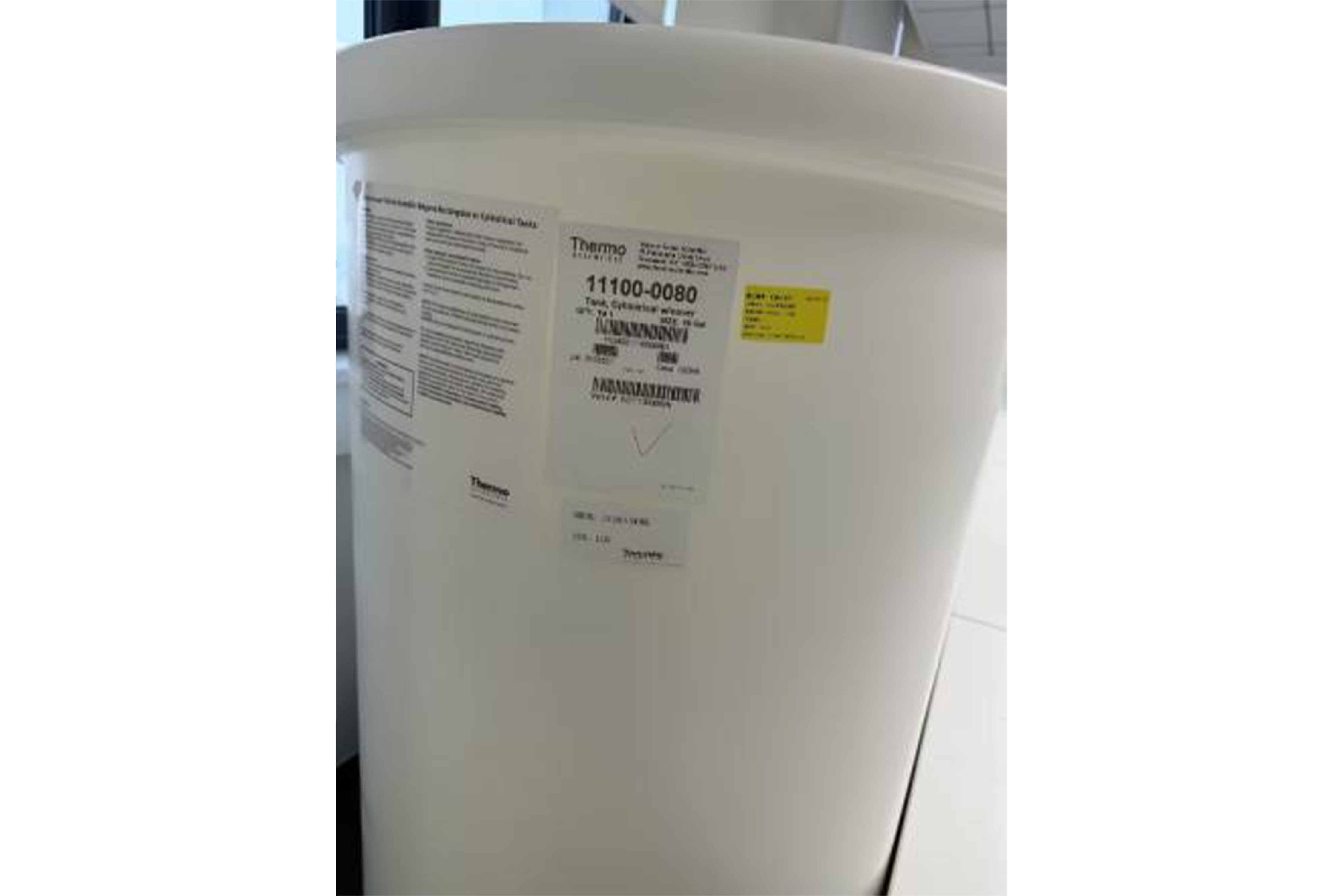

LePure 300L Plastic Mixing Vessel

The LePure 300L Plastic Mixing Vessel is a high-performance, corrosion-resistant solution preparation system designed for pharmaceutical, biotech, and chemical applications requiring non-metallic, contamination-free environments.

Key Specifications:

- Capacity: 300L working volume

- Material: USP Class VI polypropylene (PP) or PTFE-lined construction (optional)

- Mixing System: Top-mounted agitator with adjustable speed (10–150 RPM)

- Temperature Range: -20°C to +80°C (optional heating/cooling jacket)

- Ports: Multiple 1.5" TC/SAN/ISO flanges for sensors, probes, and feed lines

- Compliance: Meets cGMP, FDA 21 CFR Part 177, and USP <88> Class VI standards

Features:

✔ Non-reactive polymer construction – Ideal for sensitive media, buffers, and corrosive chemicals

✔ Seamless rotational molding – Eliminates joints for superior cleanability and drainage

✔ Transparent graduated markings – Optional backlit illumination for visibility

✔ Mobility & Stability – Stainless steel frame with lockable casters for easy relocation

✔ Gravimetric Control (optional) – Integrated load cells (±0.25% accuracy) for precise dispensing

Applications:

- Biopharma: Buffer preparation, cell culture media mixing

- Chemical Processing: Acid/base solutions, solvent handling

- Food & Beverage: Flavor blending, additive incorporation

Customization Options:

- Sterilization: CIP/SIP compatibility

- Additional Ports: Extra fittings for pH/DO probes, filtration, or transfer lines

- Automation: PLC-controlled mixing and dispensing

The LePure 300L ensures contamination-free processing with its smooth interior (Ra ≤0.5μm) and modular design for seamless integration into production workflows.

(Note: "LePure" is a registered trademark and remains untranslated.)