Device built-in

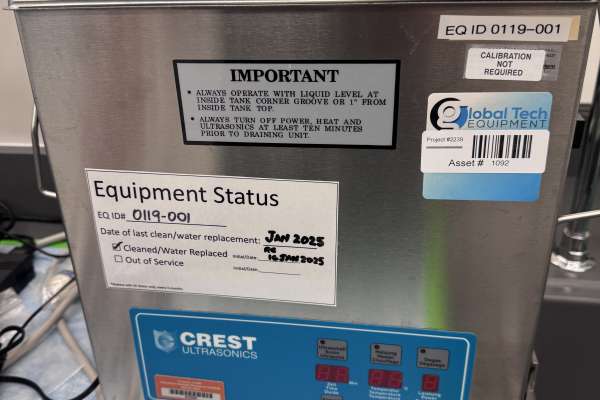

Crest Ultrasonic Cleaner Model 1100D (with Stainless Steel Basket) - A Comprehensive Introduction

In modern laboratories, industrial manufacturing, electronics repair, jewelry, healthcare, and even creative arts, efficient and precise cleaning is essential. The Crest Ultrasonic Cleaner Model 1100D, a classic mid-capacity benchtop ultrasonic cleaning device, has become the ideal choice for numerous professional users due to its reliable performance, user-friendly design, and wide applicability.

1. Product Overview & Positioning

Crest is a well-known American brand of ultrasonic cleaners, renowned for manufacturing robust and performance-stable products. The Model 1100D is a highly popular unit in their lineup, featuring an internal capacity of 0.9 gallons (approximately 3.4 liters), placing it in the medium-capacity range for benchtop cleaners. Its standard inclusion of a Stainless Steel (SS) Basket significantly enhances usability and cleaning effectiveness. This unit is primarily aimed at users who need to clean small batches of high-value or high-cleanliness components daily, perfectly balancing cleaning power, operational convenience, and cost-effectiveness.

2. Core Technology & Working Principle

The core of ultrasonic cleaning technology is the "cavitation effect." The Model 1100D is equipped with high-performance piezoelectric ceramic transducers (typically operating at 40 kHz) mounted on its bottom or sides. When activated, these transducers convert electrical signals into high-frequency mechanical vibrations, which are transmitted through the stainless steel tank walls into the cleaning solution.

Cavitation Formation:The high-frequency sound waves create countless microscopic vacuum bubbles (cavitation bubbles) in the liquid. These bubbles rapidly grow and implode violently under alternating pressure cycles.

Powerful Cleaning Force:The implosion of these bubbles generates localized, intense shockwaves and micro-jets (with instantaneous temperatures reaching up to 5000°C and pressures exceeding 1000 atmospheres). This energy penetrates every crevice, hole, and recessed surface of the item being cleaned, thoroughly dislodging stubborn contaminants like dirt, dust, grease, polishing compounds, and particulate matter without causing any physical damage to the item itself. This constitutes an "all-reaching" cleaning method, effective even in corners inaccessible to traditional tools like brushes or swabs.

3. Key Features & Design Advantages

Robust Construction:

Housing:Features a sturdy molded plastic shell offering good impact resistance and chemical corrosion resistance, protecting internal components.

Tank:The entire cleaning tank is constructed from high-quality stainless steel (typically Grade 304 or 316), resistant to corrosion, easy to clean, and efficient at transmitting ultrasonic energy.

Importance of the Standard Stainless Steel (SS) Basket:

Protects Workpieces:Placing delicate items directly on the tank bottom might cause slight abrasion against the vibrating transducer area. Using the basket isolates items from the tank bottom, providing cushioning and protection.

Easy Loading/Unloading:After cleaning, simply lift the entire basket to remove all parts easily, avoiding the need to fish items out by hand, which is more convenient and hygienic.

Promotes Circulation:The mesh design allows free flow of the cleaning solution, ensuring even distribution of ultrasonic energy, while allowing dislodged contaminants to settle at the tank bottom, preventing recontamination.

User-Friendly Operation & Control System:

Digital Timer:Typically equipped with an adjustable digital timer (e.g., 0-30 minutes), allowing users to set precise cleaning times based on soil level; the unit auto stops when time elapses.

Heating Function (Common Feature):Many 1100D models include a heater (up to ~70°C). Heat accelerates chemical reactions and reduces grease viscosity, significantly enhancing cleaning efficiency, especially for heavy oils.

Degas Function:When fresh solution is added, dissolved gases can absorb ultrasonic energy, reducing cavitation. The degas mode runs at high power initially to expel these gases, optimizing cleaning performance.

Safety & Environmental Considerations:

A lid is typically provided to reduce solvent evaporation, heat loss, and prevent splashing, ensuring safer operation.

Efficient cleaning can reduce the consumption of harsh chemical solvents, aligning with environmental considerations.

4. Application Examples

Laboratories:Cleaning glassware (beakers, cylinders, pipettes), lab tools, sample containers, ensuring no residual contamination.

Electronics & Precision Manufacturing:Cleaning circuit boards (PCBs), semiconductor components, precision molds, mechanical parts (removing cutting oil, metal debris).

Jewelry:Thoroughly cleaning dirt, grease, and oxides from crevices in rings, necklaces, watches, restoring shine.

Medical & Dental:Cleaning surgical instruments, dental tools, dentures as a high-standard pre-disinfection step.

Optics & Eyewear:Cleaning glasses, lenses, frames (removing oils, fingerprints).

Automotive Repair:Cleaning carburetors, fuel injectors, spark plugs, precision bearings.

Arts & Collectibles:Cleaning coins, stamps, models.

5. Usage Notes

Select Appropriate Cleaning Solution:Do not use plain water for greasy/oily parts. Choose specialized ultrasonic cleaning solutions (alkaline, acidic, solvent-based, or eco-friendly aqueous) based on the contaminant. Water alone is suitable only for rinsing or dust removal.

Liquid Level:Maintain the solution level between the MIN and MAX marks. Too low can damage transducers; too high may cause overflow.

Part Placement:Avoid placing items directly on the tank bottom. Use a beaker or sealed bag (submerged) for very small parts.

Safe Operation:Do not place hands in the solution while the unit is operating. Do not use the heater with flammable solvents.

6. Conclusion

The Crest Ultrasonic Cleaner Model 1100D (with Stainless Steel Basket) is a well-designed, practical, and reliable industrial-grade benchtop cleaning system. It effectively combines efficient ultrasonic cavitation, convenient heating/timer functions, and user-friendly accessories (SS basket), offering a superior cleaning solution compared to traditional manual methods. Whether for demanding industrial production or precise laboratory research, it performs exceptionally well, extending tool life and improving workflow efficiency, making it a dependable cleaning assistant.