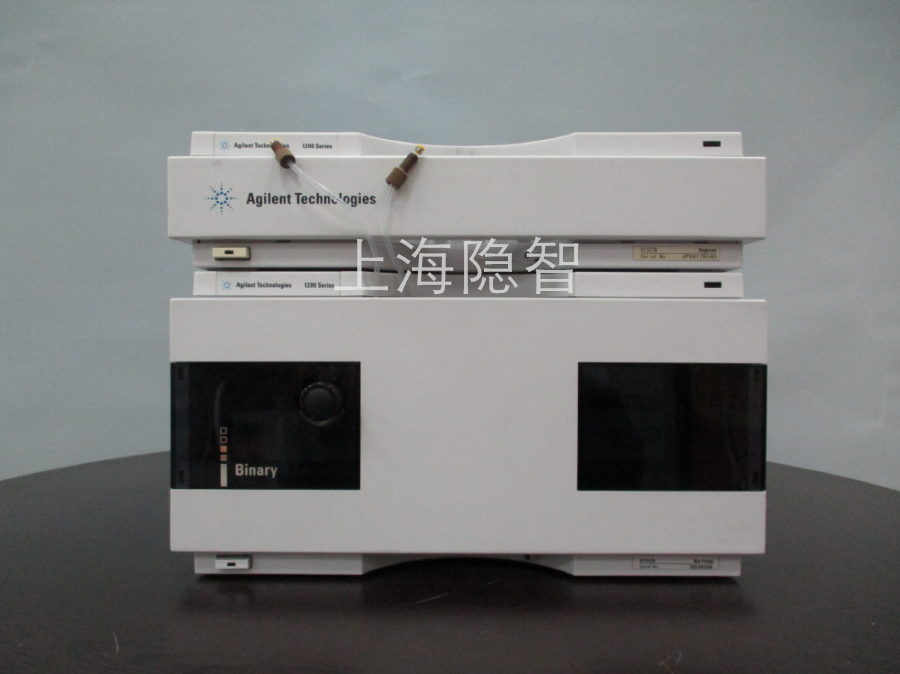

Device built-in

Introduction to Agilent LC Modules (Bin Pump and Degasser)

Agilent Technologies, a global leader in analytical instrumentation, offers high-performance liquid chromatography (HPLC/UHPLC) modules, including the binary high-pressure gradient pump (Bin Pump) and online degasser, which serve as the core components for stable and reliable mobile phase delivery and degassing. Below is a detailed introduction to the technical features, performance advantages, and application value of these two critical modules.

Binary High-Pressure Gradient Pump (Bin Pump)

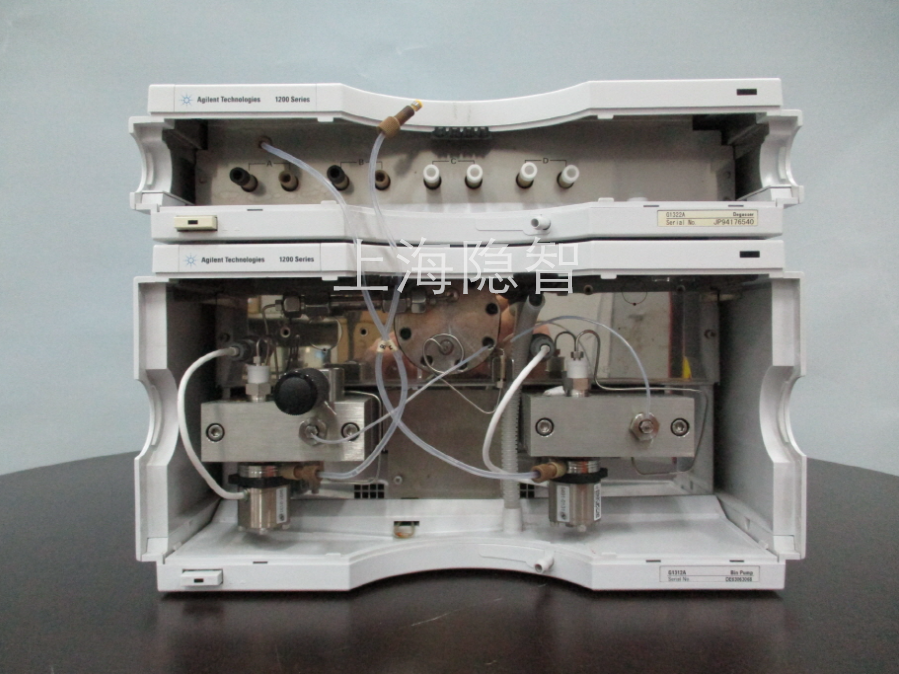

The Agilent Bin Pump is a precision binary high-pressure gradient pump featuring a dual-piston, serial design that enables accurate flow control and gradient mixing. The pump typically operates within a flow rate range of 0.001–10 mL/min (model-dependent) and can withstand pressures exceeding 600 bar, making it fully compatible with ultra-high-performance liquid chromatography (UHPLC) requirements. Its key advantages include:

Precise Flow Control: Utilizing advanced Active Inlet Valve (AIV) technology and a high-precision piston drive mechanism, the pump ensures flow accuracy better than ±1% and repeatability better than 0.075% RSD, guaranteeing retention time stability. The AIV design also minimizes bubble formation and enhances low-pressure mixing efficiency.

Intelligent Compression Compensation: Equipped with real-time compression compensation, the pump automatically corrects for mobile phase compressibility effects, ensuring accurate gradient formation—particularly critical for low-dispersion-volume UHPLC applications.

Rapid Gradient Formation: With a small system delay volume (typically <100 µL) and fast gradient formation, the pump enables high-speed chromatographic separations, improving analytical throughput. Combined with a high-precision proportioning valve, gradient accuracy can reach ±0.5%.

Broad Solvent Compatibility: The pump head is constructed from corrosion-resistant ceramic and stainless steel, allowing compatibility with a wide range of mobile phases—from pure water to 100% organic solvents, including buffered salt solutions and acidic/alkaline solvents.

Online Degasser Features

The Agilent online degasser employs patented membrane degassing technology, using specially designed gas-permeable tubing and vacuum pressure to efficiently remove dissolved gases from the mobile phase. Its key technical features include:

High-Efficiency Degassing: Removes up to 99.9% of dissolved oxygen and other gases, preventing bubble formation and avoiding issues such as baseline noise, retention time drift, and column efficiency degradation.

Multi-Channel Design: Standard configurations typically include four degassing channels (expandable), allowing simultaneous degassing of multiple solvents for both isocratic and gradient elution modes.

Maintenance-Free Operation: No consumable parts are required, eliminating the need for membrane replacement and ensuring long service life. The modular design allows for easy integration into LC systems.

Smart Monitoring: Some advanced models feature real-time degassing efficiency monitoring, displaying the degassing status to ensure optimal system performance.

System Integration and Application Value

The synergistic operation of Agilent’s Bin Pump and degasser forms the core mobile phase delivery system for liquid chromatography. The combination of precise binary gradient mixing and efficient degassing provides a stable and reliable solution for chromatographic analysis. This system is particularly well-suited for:

- Pharmaceutical Analysis: Meeting stringent pharmacopeial (USP/EP) requirements for mobile phase precision and stability

- Food Safety Testing: Enabling accurate separation and quantification of trace components in complex matrices

- Metabolomics Research: Supporting highly reproducible gradient elution separations

- Environmental Monitoring: Ensuring long-term retention time consistency in sequential analyses

Agilent’s LC modules incorporate smart design principles, featuring comprehensive self-diagnostic functions that monitor system pressure, flow rate, and degassing status in real time, allowing for early detection of potential issues. Through software platforms such as Agilent OpenLAB CDS, users can achieve remote monitoring and method control, enhancing laboratory automation.

From a maintenance perspective, the Bin Pump’s modular design allows for easy replacement of key components (e.g., piston seals, inlet valves), significantly reducing maintenance costs. Meanwhile, the degasser operates virtually maintenance-free, offering a true "install-and-forget" convenience.

The Agilent Bin Pump and degasser combination represents the industry benchmark for LC solvent delivery systems. With outstanding performance, reliable stability, and user-friendly design, they serve as an ideal choice for applications ranging from routine QC laboratories to advanced research institutions, providing a solid foundation for diverse chromatographic analyses.