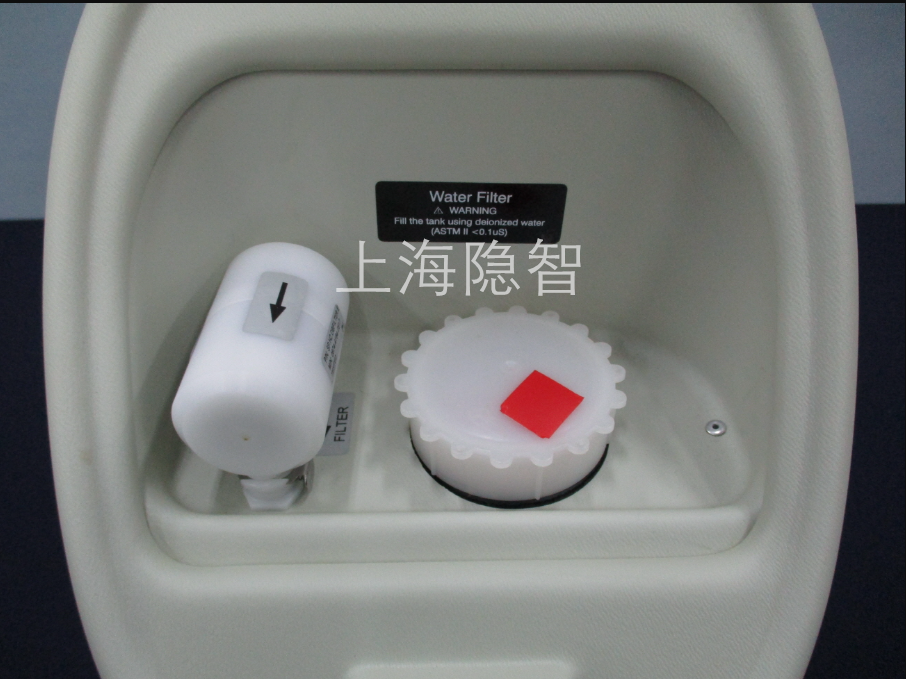

Device built-in

F-DGSi Hydrogen Generator WM.H2.120.V3 Technical Overview

Core Specifications and Design Philosophy

The F-DGSi WM.H2.120.V3 is a laboratory-grade hydrogen generator utilizing Proton Exchange Membrane (PEM) technology, specifically designed for precision applications such as gas chromatography (GC) and fuel cell testing. Its key advantages include:

- Ultra-High Purity Output: Three-stage purification (catalytic deoxygenation → molecular sieve adsorption → palladium membrane filtration) delivers 99.9999% pure hydrogen (oxygen content <0.1 ppm, dew point <-70°C), meeting UHP-grade gas standards.

- Intelligent Electrolysis Control: Built-in IR sensors monitor electrolyzer status in real time, automatically adjusting gas production rates (10-120 mL/min adjustable) to reduce energy consumption by 40% compared to conventional electrolysis.

Innovative Technical Features

Safety Protection System

- Triple safety mechanisms: Pressure sensors (0-8 bar adjustable), hydrogen leak alarms (triggered at <1% LEL), and automatic pressure relief valves, certified to ATEX explosion-proof standards.

- Fully enclosed electrolyzer design with zero-corrosion KOH alternative electrolyte, eliminating leakage risks.

Modular Smart Management

- 7-inch touchscreen displays real-time flow rate, purity, and pressure curves, supporting data export (USB/RS232 interfaces).

- Patented "Eco-Mode" technology: Automatically switches to low-power state (<5W) during standby, extending membrane lifespan to over 5 years.

Typical Applications

- Gas Chromatography: As FID detector fuel gas, reduces baseline noise by 30% compared to gas cylinders.

- Materials Research: Provides stable hydrogen for ALD (Atomic Layer Deposition) equipment, with purity surpassing cylinders (99.999% vs 99.99%).

- Teaching Labs: Compact dimensions (28×18×35 cm) suit benchtop placement, offering instant on-demand gas without storage facilities.

Operation and Cost Efficiency

- Low-Maintenance Design: Only requires annual replacement of deionized water (built-in 18MΩ·cm ultrapure water module), with no moving parts prone to wear.

- Economic Advantage: Saves over 60% in costs compared to gas cylinders across a 3-year lifecycle, while eliminating transportation and storage risks.

Industry Positioning: The WM.H2.120.V3 redefines laboratory hydrogen supply with its "safe, on-demand production" concept, particularly suited for users demanding stringent gas purity and operational safety. Certified to ISO 9001/CE standards, it has become the standard hydrogen solution for hundreds of laboratories across the EU and North America.