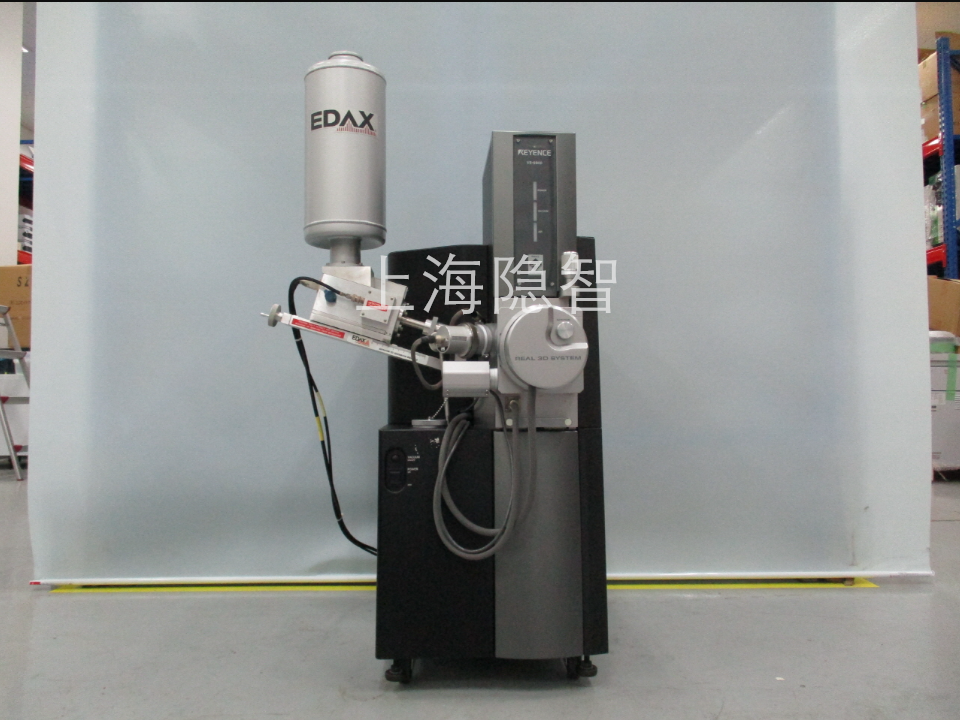

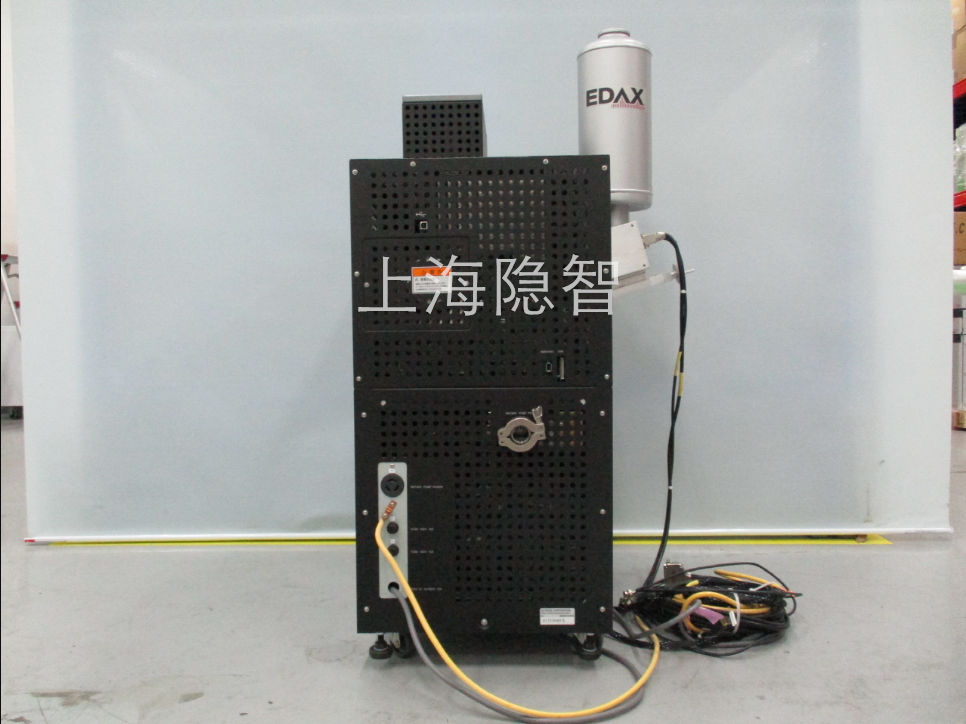

KEYENCE 3D Surface Measurement Microscope VE-9800

The KEYENCE VE-9800 is a high-precision 3D surface measurement microscope that utilizes advanced optical technology and image processing algorithms to achieve nanometer-level surface topography measurements. This system is widely used in semiconductor, electronic components, precision machinery, and materials science fields, providing accurate measurement solutions for surface roughness, step height, and micro-topography parameters.

Price:Negotiable

Service charge: 10% of the transaction price

- 设备品牌:Keyence

- 设备安装时间:2006

- 设备所在地:

- 设备型号:VE-9800

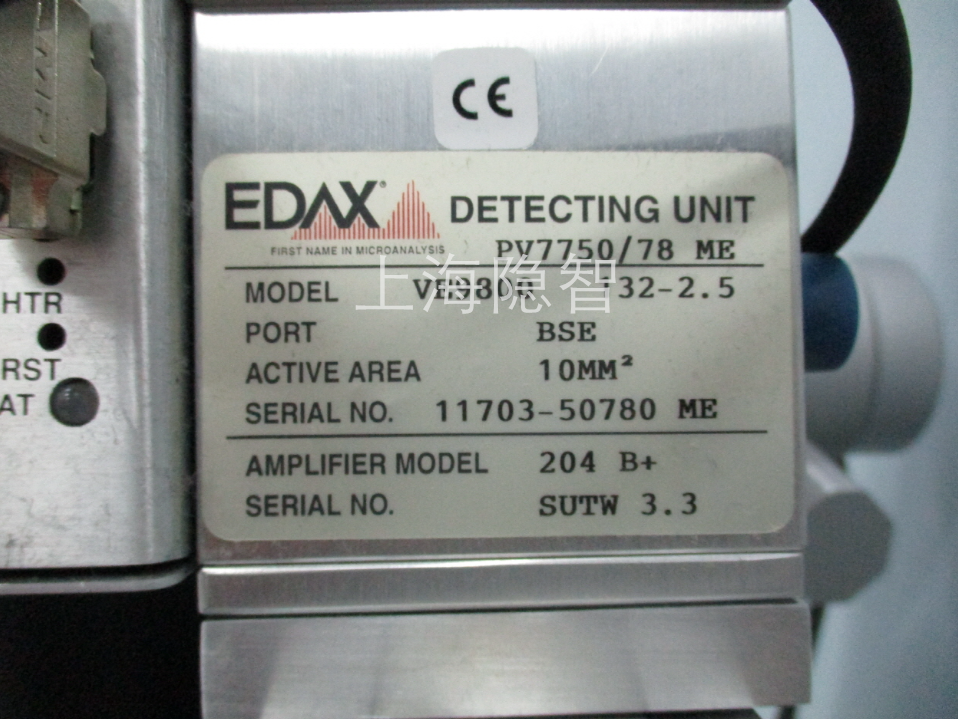

- 设备序列号:1170350780

- 电压:

- 电频:

- 尺寸:

- 重量:

Device built-in

KEYENCE 3D Surface Measurement Microscope VE-9800 - English Introduction

Product Overview

The KEYENCE VE-9800 is a high-precision 3D surface measurement microscope that utilizes advanced optical technology and image processing algorithms to achieve nanometer-level surface topography measurements. This system is widely used in semiconductor, electronic components, precision machinery, and materials science fields, providing accurate measurement solutions for surface roughness, step height, and micro-topography parameters.

Core Technical Features

- Ultra-High Resolution Measurement System

- Employs white light interferometry with vertical resolution up to 0.1nm and horizontal resolution of 0.5μm

- Equipped with high-precision piezoelectric displacement stage for nanometer-level Z-axis positioning accuracy

- Supports continuous zoom observation from 10x to 2000x magnification

- Intelligent Measurement Capabilities

- Auto-focus and automatic measurement functions significantly improve efficiency

- Supports multiple measurement modes including multi-point measurement, line roughness, and area roughness analysis

- Built-in library of 200+ ISO/JIS standard parameters to meet various industry requirements

- Advanced Image Processing Technology

- Proprietary interference fringe analysis algorithm effectively eliminates environmental vibration effects

- Real-time 3D rendering for immediate surface topography visualization

- Supports advanced analysis functions including surface texture analysis and profile extraction

Typical Applications

- Semiconductor Industry: Wafer surface defect inspection, photoresist thickness measurement

- Precision Manufacturing: Cutting tool edge wear analysis, mechanical component surface quality inspection

- Materials Research: Thin film thickness measurement, coating surface topography analysis

- Electronic Components: PCB trace height measurement, solder joint 3D morphology inspection

System Advantages

- User-Friendly Operation: Intuitive interface with highly automated measurement workflows

- Measurement Stability: Vibration-resistant design ensures >99% measurement repeatability

- Comprehensive Data Output: Generates complete datasets including 2D/3D images, cross-sectional profiles, and roughness parameters

- High Expandability: Supports integration with automation equipment for batch inspection

Conclusion

The KEYENCE VE-9800, with its nanometer-level measurement accuracy, intelligent operation, and powerful analysis capabilities, has become the ideal tool for micro/nano-scale surface measurement. Whether for quality analysis in R&D laboratories or process control in production lines, it delivers reliable measurement data to help users improve product quality and production efficiency.