High-Pressure Switching Valve

The High-Pressure Switching Valve is a critical component in fluid control systems, designed to rapidly switch or divert flow paths under high-pressure conditions (typically ≥10 MPa). Its core functions include multi-channel selection, flow direction control, and pressure isolation, making it widely applicable in petrochemicals, pharmaceuticals, chromatographic analysis, and supercritical fluid extraction.

Price:Negotiable

Service charge: 10% of the transaction price

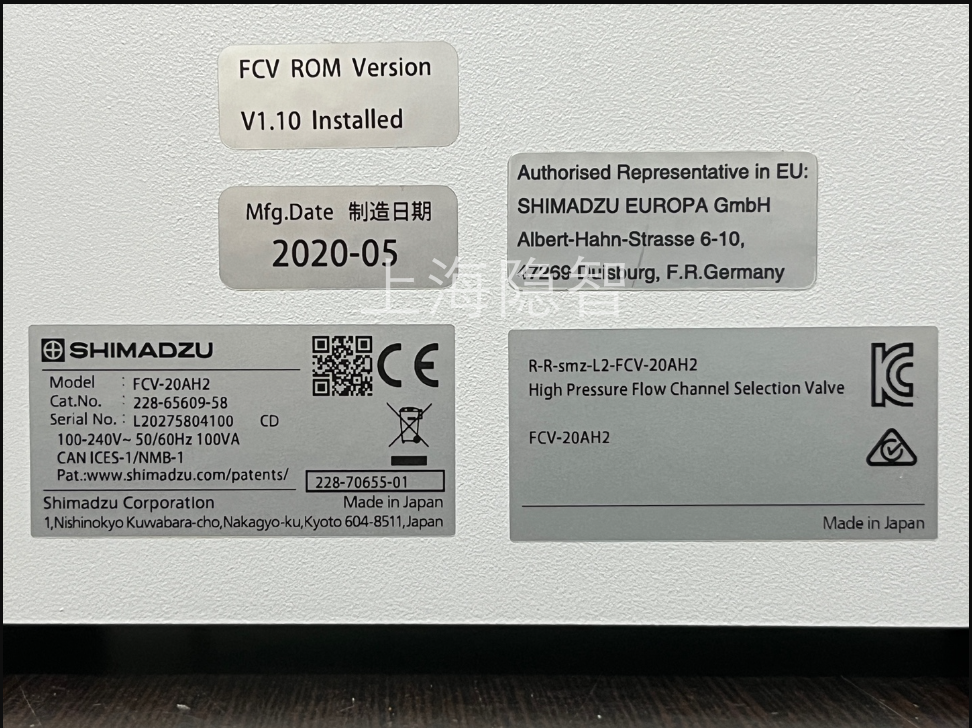

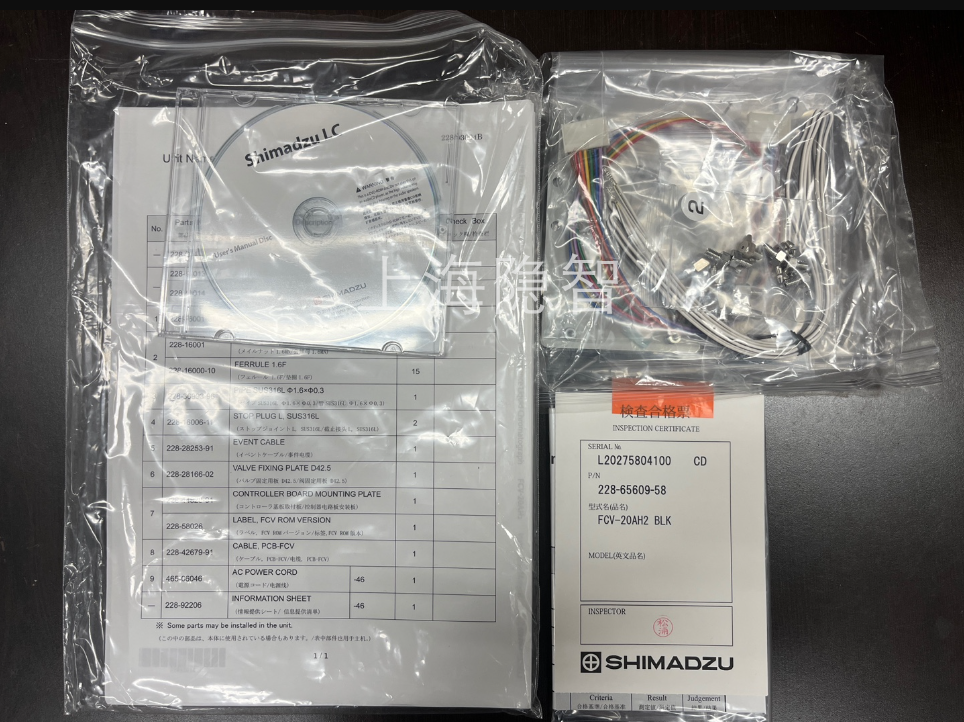

- 设备品牌:Shimadzu

- 设备安装时间:2020

- 设备所在地:

- 设备型号:FCV-20AH2

- 设备序列号:L20275804100

- 电压:100-240V

电频:50-60Hz

- 尺寸:

- 重量:

Device built-in

Introduction to High-Pressure Switching Valve

The High-Pressure Switching Valve is a critical component in fluid control systems, designed to rapidly switch or divert flow paths under high-pressure conditions (typically ≥10 MPa). Its core functions include multi-channel selection, flow direction control, and pressure isolation, making it widely applicable in petrochemicals, pharmaceuticals, chromatographic analysis, and supercritical fluid extraction.

Key Features

High-Pressure Resistance:

- The valve body is constructed from 316L stainless steel or Hastelloy, with seals made of polyetheretherketone (PEEK) or graphite, capable of withstanding pressures up to 70 MPa for use in supercritical CO₂ or high-pressure liquid systems.

- Dynamic sealing structure ensures zero leakage (leak rate <1×10⁻⁹ mbar·L/s) even during frequent switching.

Flexible Switching Modes:

- Supports electric, pneumatic, or manual actuation, with switching times as fast as 50 ms (electric type), meeting real-time requirements for online analysis systems.

- Multiple flow path configurations (e.g., 6-port, 8-port, 10-port) for bidirectional or multidirectional fluid distribution.

Low Dead Volume & Corrosion Resistance:

- Mirror-polished internal flow channels with dead volume <0.5 μL to prevent cross-contamination.

- Special coatings or perfluoro-material options for resistance to acids, alkalis, and organic solvents.

Technical Specifications

- Operating Pressure Range: 0.1–70 MPa (model-dependent).

- Temperature Adaptability: -20–200°C (standard), with high-temperature models up to 350°C.

- Electrical Interface: IP65 protection rating, compatible with 24 VDC or 220 VAC power supply.

Typical Applications

- Chromatography Systems: Flow path switching for GC/LC injection or column switching.

- Energy Industry: Controls water injection in oil wells or natural gas pipeline diversion.

- Laboratory Equipment: Integrated into supercritical extractors or pressurized reactor systems.

Selection & Maintenance Tips

- Select valve materials based on fluid corrosivity (e.g., titanium alloy for chlorine-containing media).

- Regularly inspect seal wear; dynamic seals should be replaced every 5,000 cycles.

Renowned for high reliability and long service life, this valve is a standardized solution for high-pressure fluid control applications.